Table of Contents

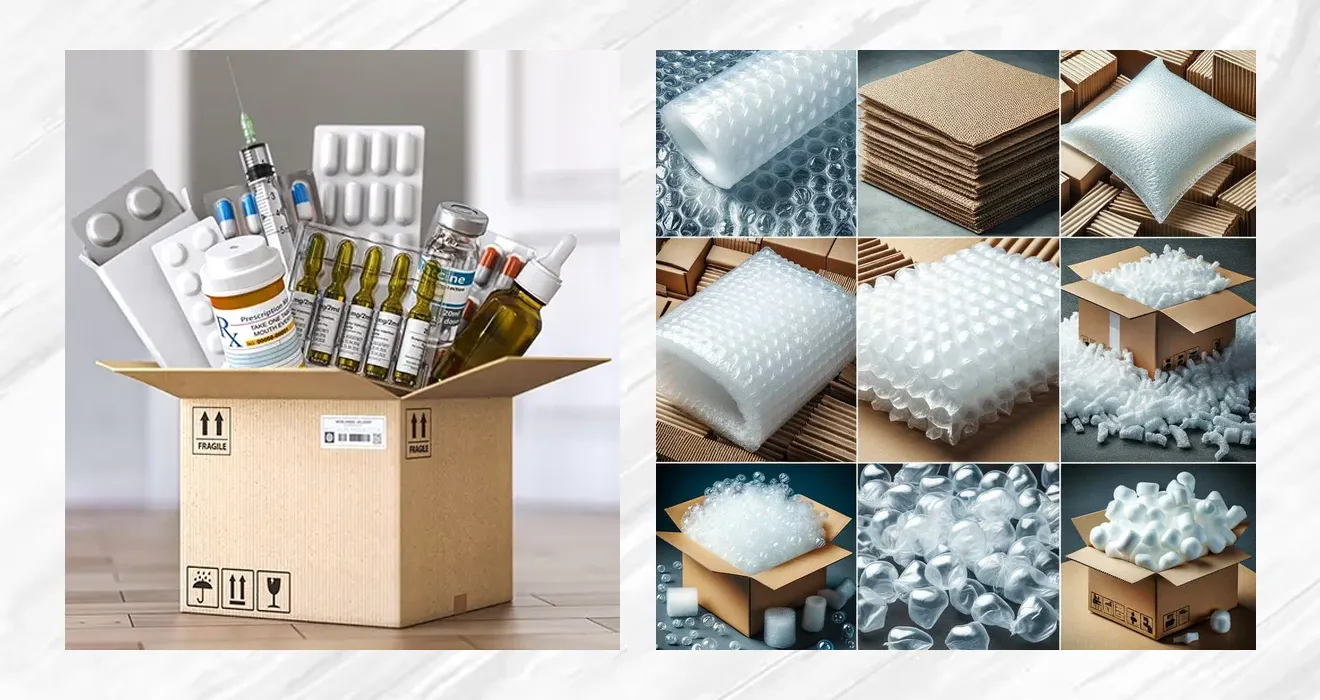

Every medicine we come across carries a long and complex journey behind it. Before it reaches a patient’s hands, it travels through multiple environments—manufacturing floors, storage rooms, distribution hubs, and retail counters. At every step, it faces different risks such as moisture, light exposure, temperature shifts, and physical pressure. Most people only notice the final box or pouch they open, but the real safety work happens much earlier, woven into the protective layers that enclose each product.

Imagine a simple tablet strip used during a seasonal illness. It looks small, almost insignificant. But its entire integrity depends on the way it is sealed, cushioned, labelled, and handled. If even one layer of its packaging fails, the medicine may lose its effectiveness long before someone consumes it. The same applies to a vial that needs steady temperature, a test kit that must stay uncontaminated, or a fragile diagnostic component that cannot afford shock during transit.

This unseen world of protective packaging has grown into a dedicated science over the years. It checks the balance between material strength, design suitability, product sensitivity, regulatory expectations, and user convenience. In the pharmaceutical industry, the purpose of packaging is not limited to aesthetics; it directly supports patient well-being. The layers around a medicine are not accessories—they are safeguards.

Understanding the types of protective packaging in the pharmaceutical industry helps us see how these layers work together. When each layer is designed correctly, it becomes part of a dependable system that maintains product quality from production to patient use.

Types of Protective Packaging

Protective packaging in pharma is generally organised into three interconnected layers. Each plays a distinct role, yet all three depend on one another to maintain product stability throughout its lifecycle.

Primary packaging

Primary packaging is the closest shield a product has. It stays in direct contact with the medicine and forms the first barrier against all external influences.

In solid-dose medicines, the most familiar format is a blister pack. Its sealed cavities keep individual tablets secure, limit moisture exposure, and prevent unnecessary handling. A tablet remains untouched until the user pushes it out—an everyday action backed by strong protective intent.

For liquid medicines, vials and ampoules are common. These offer controlled environments for injectables, serums, and sensitive formulations. Their structure prevents contamination and ensures the medicine remains stable until the moment of administration. Bottles and jars are another primary layer mainly used for syrups, suspensions, capsules, and powders. Many of these come with tamper-evident or child-resistant closures to add an extra layer of safety.

Flexible primary packaging also plays an important role. Small-dose medicines, bulk powders, and diagnostic materials often come in sachets or medical-grade pouches. These are easy to transport and provide dependable protection against humidity and handling friction.

Across these examples, primary packaging acts like a personal enclosure around each dose—simple on the outside but engineered to preserve the medicine’s intended performance.

Secondary packaging

While primary packaging protects the medicine itself, secondary packaging protects the primary layer. This step becomes essential for communication, product grouping, safe stacking, and secure distribution.

Carton boxes are the most well-known form of secondary protection. They hold blister strips, small vials, syringes, or pouches together, preventing them from moving or rubbing during handling. These cartons also carry key instructions such as dosage guidance, expiry dates, and batch identification. Even though this information seems routine, it significantly contributes to patient safety.

Secondary packaging often includes inserts or separators to avoid movement inside cartons. This helps medicines stay organised and reduces the chance of physical stress during storage or transit. Shink wraps also appear in this layer, especially when multiple primary packs need bundling. They keep units intact and discourage unauthorised access.

Overall, secondary packaging ensures that medicines remain orderly, identifiable, and protected as they move through warehouses, retail shelves, and supply chain checkpoints.

Tertiary packaging

The third layer focuses on bulk transport. Tertiary packaging rarely reaches end users, but it is vital for operational safety at scale.

Large corrugated boxes, firm crates, and packaging-grade pallets form this layer. Their purpose is to consolidate multiple secondary units into a single manageable load. This helps products withstand stacking, shifting, and long movements across logistics networks.

Stretch films, pallet wraps, and strapping materials further secure these boxes during shipments. Their role may appear simple, yet they reduce the possibility of damage from vibration, compression, or accidental impact.

Tertiary packaging acts like the armour of the supply chain. It ensures that pharmaceutical items make it from manufacturing facilities to distributors and retail establishments without compromise.

Protective Packaging Materials

The strength of a packaging system depends heavily on the materials used. Every material brings a unique benefit, and choosing the correct one determines how reliably a medicine will endure its journey.

Plastics

Plastic remains one of the most adaptable materials in pharmaceutical packaging. Its ability to take shape, resist moisture, and stay lightweight makes it suitable for blister cavities, bottles, caps, test components, and flexible pouches. In some cases, plastics help create sterile barriers or controlled environments needed for sensitive items.

Paper and cardboard

Although not suited for direct contact with most medicines, paper-based materials serve as trusted secondary and tertiary layers. They offer rigidity, cushioning, and ample space for important information. Their recyclability is another plus, especially when manufacturers prefer sustainable packaging pathways.

Aluminium

Aluminium plays a key role in products that must stay shielded from light, oxygen, or humidity. Foils, laminates, and seals made from aluminium help keep sensitive medicines stable over time. Its excellent barrier properties make it one of the most dependable materials for blister backing and pouch sealing.

Glass

Glass has long been used for pharmaceutical storage, especially for injectables and formulations requiring a completely neutral container. It does not react with contents, and it maintains a sterile environment when sealed correctly. For certain medicines, glass remains the safest choice due to its chemical stability.

Temperature-focused materials

For items that depend on cold-chain conditions, specialised temperature-maintaining materials become essential. Insulated liners, cooling packs, and protective foams help preserve the required temperature range until the medicine reaches its destination. These materials ensure that thermo-sensitive items stay potent despite external temperature fluctuations.

Each material has its own place, but the key lies in choosing the right material for the right product. Protective packaging is strategic—its purpose extends far beyond appearance.

Highlighting Innovative Protective Packaging Solutions

Innovation in pharmaceutical packaging grows rapidly because new formulations, delivery systems, and logistics challenges continue to appear. Modern protective solutions often combine safety with convenience, aiming to withstand real-world handling while simplifying the user experience.

Child-resistant closures, for instance, reduce accidental access without complicating usage for adults. Medical-grade pouches with improved seal strength help protect diagnostic items during long-distance shipping. Tamper-evident strips also play a role in maintaining trust by making any interference immediately noticeable.

Some emerging solutions focus on frictionless dispensing, easy-tear formats, or improved sample protection for diagnostic kits. Others enhance durability using reinforced films or hybrid materials that provide better cushioning without increasing weight. Many solutions also improve sustainability by using recyclable or reduced-material designs while protecting the product with the same level of dependability.

These innovations show how packaging continues to evolve, adapting to industry needs and enhancing product safety from manufacturing to the final point of use.

Conclusion

Protective packaging is more than an external covering; it is an essential safeguard that preserves the quality, usability, and safety of every pharmaceutical product. By understanding the types of protective packaging in the pharmaceutical industry, it becomes clear how different layers—primary, secondary, and tertiary—work together to create reliability throughout the entire supply chain.

From blister packs that protect tablets individually to insulated systems that maintain temperature-sensitive formulations, each component plays a role in a medication’s journey. Materials such as plastics, glass, aluminium, and cardboard bring their own strengths and ensure that each product reaches the hands of patients in optimal condition.

As technology advances, protective packaging continues to grow more efficient, more user-friendly, and increasingly aligned with modern healthcare needs. Whether the goal is preventing contamination, enhancing convenience, or improving stability, the right packaging solution makes all the difference.

If you are looking for dependable protective packaging or lab consumable solutions, you may explore available options here:

👉 https://evoindustries.in/